Home BOM PS LO DIV Op-Amp RF Mixer Connect

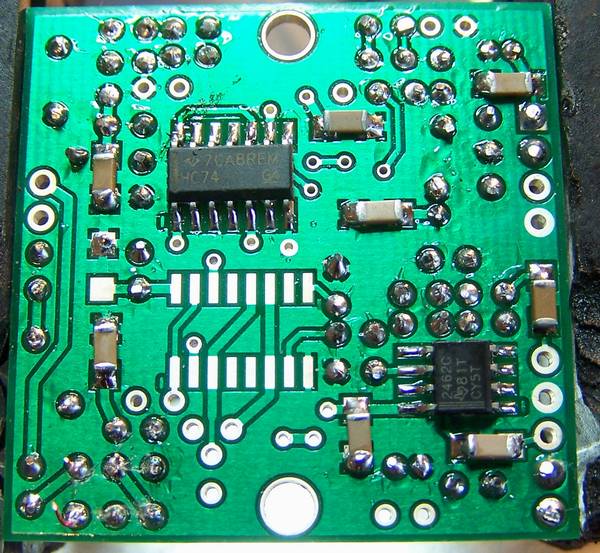

V – Softrock Lite V6.2 – RF Input

In this stage, we will be adding the signal path up to the point that the signal is coupled to the OPAmps (R14) and to the mixer (R8 and R9)

Parts

|

Designation |

Description |

Type

Component |

Quantity |

|

L1 |

5.0 uH |

38T #30 on T25-2 (red) Toroid Core (approx 14” of wire) |

1 |

|

T1 |

Transformer |

Primary: 10T #30 on T25-2 (red) Toroid Core Secondaries(2): 5T of #30 bifilar atop primary winding |

1 |

|

C20 |

0.1 uF |

SMT cap |

1 |

|

C21 |

100pF |

Ceramic Cap (“101”) |

1 |

|

C22 |

1500 pF |

Ceramic Cap (“152”) |

1 |

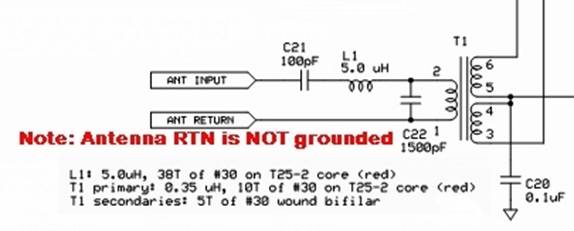

Schematic

Installation Notes

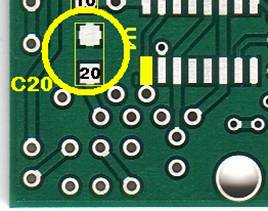

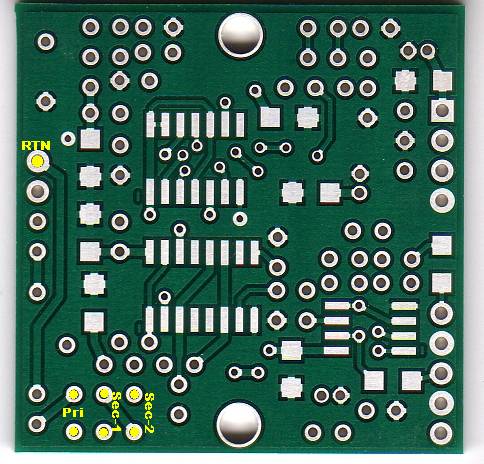

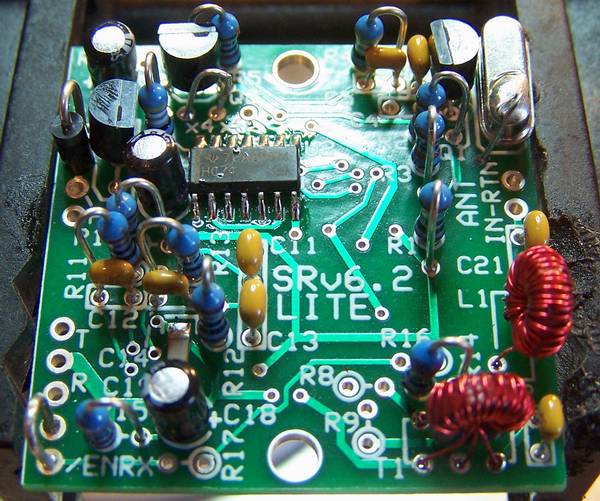

SMT Cap C20 is installed at the bottom side, lower-left:

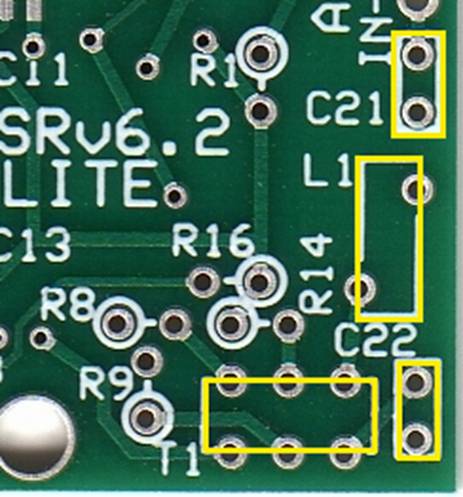

Topside Components

Ceramic Caps

c C21 (100 pF – code = “101”) and

c C22 (1500 pF – code = “152”) are installed as shown in the topside picture, above

Inductors

c

L1: wind

38 turns of #30 wire (requires about 14” of wire) onto a T25-2 (Red) toroid core.

This should produce a 5 uH inductance.

Each pass through the center of the core is counted as a turn when winding

the inductor. L1 is mounted vertically and supported by its

leads.

Be sure to remove the enamel coating on the wire before attempting to solder an

inductor lead to its associated mounting hole.

The enamel coating on the #30 wire provided in the kit does not heat

strip

very well but may be stripped by use of a small folded over piece of Emory paper where the lead is pulled through two facing surfaces of the Emory paper multiple times to sand off the enamel coating on the wire end.

See the tutorial on winding toroids for details on winding a single-winding coil.

c

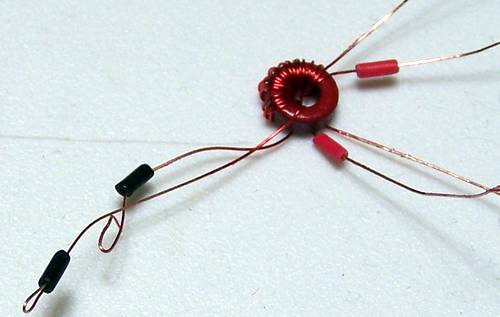

T1: This transformer has a single winding

primary and a bifilar winding secondary, wound with #30 wire onto a T25-2 (red)

toroid. The 10 turn primary winding,

using 10” of #30 wire, should yield 0.35

uH. The 5 turn secondary uses two 5”

lengths of #30 wire, twisted together into a bifilar pair that has

approximately 2-3 twists per inch.

Transformer T1 is mounted vertically and raised above the board about 1/8 of an

inch. In winding T1, first wind the

primary winding with 10 turns #30 AWG enameled wire (approximately 10” of wire)

so that the primary winding starts and ends at about the same point on the core

and is uniformly spread around the core.

Twist two 5” pieces of #30 enameled wire together and wind the secondary

windings with the windings starting and ending just slightly clockwise around

the core from where the primary winding starts and ends. After striping and tinning each transformer

lead at about 1/8 of an inch from the

core, determine the two pairs of leads of each of the secondary windings by use

of an ohmmeter.

I like to use short lengths of insulation from hookup wire to identify two of

the 3 sets of leads in these transformers.

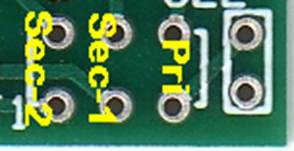

The windings and their mounting positions at the lower right-hand position on

the topside are shown below:

Either secondary winding may be designated as the first secondary winding.

c

When the transformer is positioned vertically

with its leads to the appropriate plated through-holes, solder all the leads

and cut leads flush to the bottom side of the board.

See the video

tutorial showing winding and

mounting

a similar transformer for another Softrock kit.

Tests

The inductors are the second most common causes of RX problems in the Softrock kits. Therefore, these tests are critical to the project.

Current Draw

There should be no appreciable change in current draw from the previous stage.

Resistance

c

Each of the primary plated through-holes should

show about zero ohms resistance to the antenna return hole, (RTN), on the upper

right edge of the board.

Voltages

c Apply power to the board

c

Measure the voltage (WRT Ground) at each of the

secondary terminals of the transformer T1.

Each should measure ~2.5 Vdc.

(author  measured 2.48

Vdc)

measured 2.48

Vdc)

c Power off

Scope (board remains unpowered)

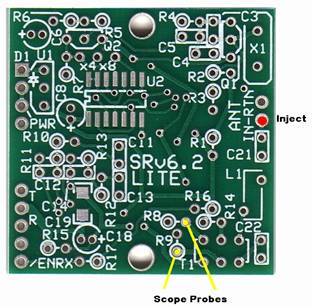

c Inject a ~2 volt p-p signal at around 7 MHz into the ANT-IN pad. Once again, you can probably just use a cutoff component lead and poke it through the empty lead hole without soldering.

c Connect the scope probes to the points shown (yellow dots) below and connect the probe ground leads to ground.

c

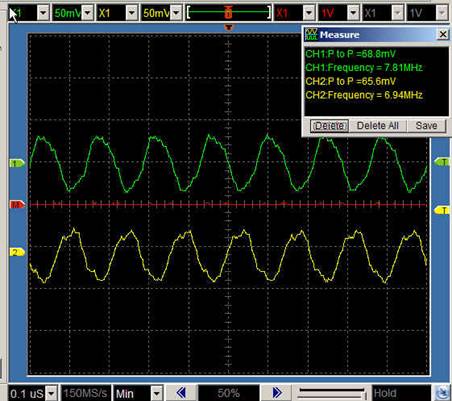

Phasing

Test: Trigger your scope with channel 1. You should have an equal

amplitude, opposite phase signal displayed. If they are in phase, you probably

aren't triggering the scope on channel 1. If either one is missing, double

check the solder connections for T1.

Your test results should resemble the fo9llowing (the key result is the phase

difference of 180 degrees):

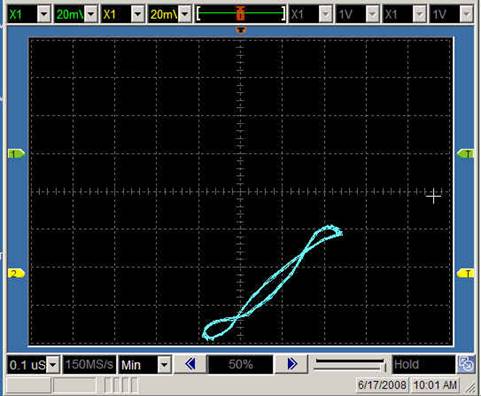

c Lissajous Pattern (X-Y) Test: Change your scope setting to “X-Y” to get a lissajous pattern of the two signals together. If the phasing is perfectly 180 degrees out of phase, we should see a single diagonal line. In reality, there will be some non-zero (but hopefully low, on the order of 5% of the input) signal shown on the scope:

Completed Stage

You have completed one of the more tedious stages in building the kit (at least, for me, the winding of toroids and stripping the enamel without breaking the leads is certainly tedious). If you have passed the tests described here, you are well on your way. The only part left is the Mixer stage, followed by connecting the radio to the outside world and actually using it..

Topside

Bottomside